Selecting the Best Flame Retardant for Electronics: Ensuring Safety and Compliance in PET Film Applications

As electronic devices become smaller and more integrated, the materials used in their construction must meet increasingly stringent fire safety standards. One critical area is the use of flame retardant PET film, a material frequently found in flexible printed circuits, battery insulations, and electronic housings. This article discusses how to choose the best flame retardant for electronics, especially when PET film is involved.

1. Why PET Film Is Used in Electronics

PET (Polyethylene Terephthalate) is widely chosen for electronic applications due to its:

- Excellent dimensional stability

- Good dielectric properties

- Cost-effective processing

- Chemical resistance

However, PET in its pure form is flammable. To meet global standards like UL94 and IEC 60695, manufacturers must use flame retardant PET film applications tailored for the electronics industry.

2. What Makes a Flame Retardant “Best” for Electronics?

To qualify as the best flame retardant for electronics, the compound must satisfy several conditions:

- Thermal Stability: It should withstand high-temperature soldering processes or board assembly lines without decomposition.

- Halogen-Free Composition: With increasing RoHS and WEEE regulations, halogen-free systems are now favored.

- Low Smoke and Toxicity: This is critical for consumer electronics and enclosed spaces.

- Low Migration: The retardant should stay embedded in the film without bleeding or leaching out, which is particularly important in custom flame retardant PET film solutions.

3. Halogen-Free vs. Halogenated Flame Retardants

In choosing flame retardants for PET, there’s a key decision between:

Halogenated Systems

- Effective at low loadings

- Cost-effective

- But restricted due to toxic byproducts during combustion

Halogen-Free Systems

- Use phosphorus, nitrogen, or mineral-based compounds

- Environmentally safe

- Favored for use in consumer and wearable electronics

Halogen-free is now often the best flame retardant for electronics due to sustainability and safety concerns.

4. Integrating Flame Retardants in PET for Electronics

Three main strategies are used:

- Additive Retardants: Mixed during film extrusion. Easier and flexible.

- Reactive Retardants: Chemically bonded to the polymer. Offer low migration and long-term stability.

- Nano Additives: Provide flame resistance without compromising film properties.

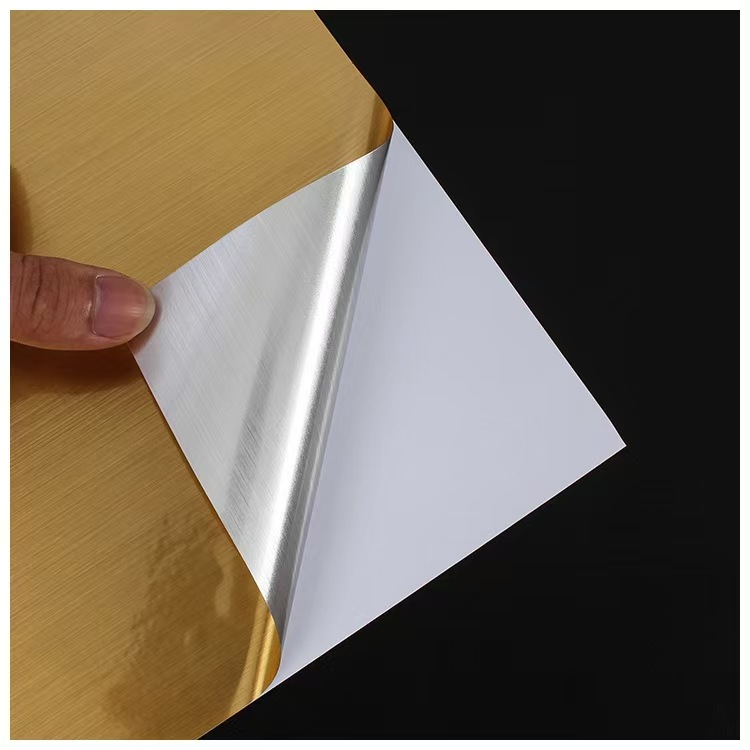

To create custom flame retardant PET film, electronics companies often test various combinations to find the optimal blend of performance, clarity, and compliance.

5. Industry Case Study: Battery Insulation Films

In lithium-ion batteries, PET is used as an outer insulation wrap. These films require:

- High dielectric strength

- Flame retardancy (UL94 VTM-0 or better)

- Heat resistance

- Mechanical durability

The flame retardant PET film applications in this case rely on phosphorus-nitrogen systems that resist combustion while maintaining flexibility.

Conclusion

Selecting the best flame retardant for electronics involves more than just meeting flammability ratings. It includes considerations of processing, long-term stability, environmental impact, and electrical performance. As electronics continue to evolve, so will the standards for materials like PET film. Ensuring that your PET formulation includes the right flame retardant is critical not just for compliance, but for product performance and consumer safety.

SEO Keywords:

best flame retardant for electronics, flame retardant PET film applications, custom flame retardant PET film, choosing flame retardants for PET, halogen-free flame retardant, electronics PET film

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.