Choosing Flame Retardants for PET: Key Factors and Industry Best Practices

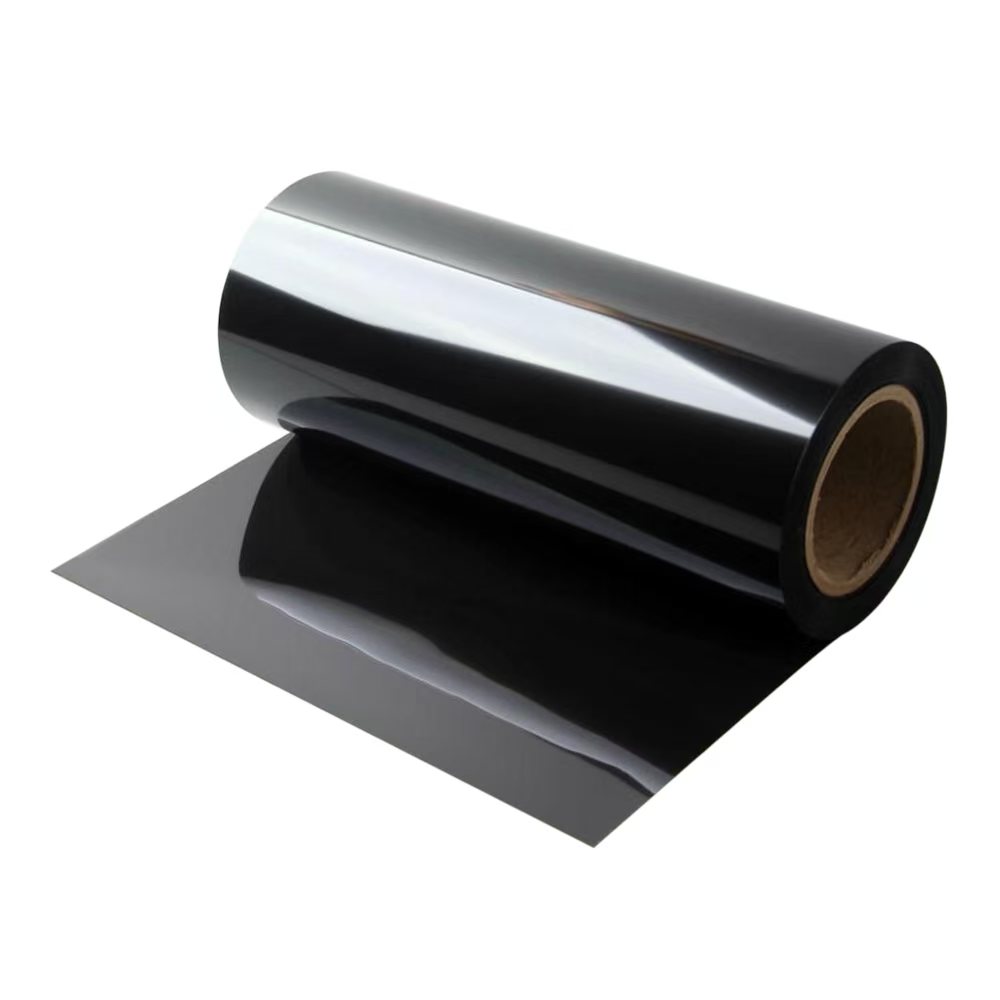

As demand for flame-retardant materials continues to rise in packaging, electronics, automotive, and construction, understanding the science behind choosing flame retardants for PET becomes increasingly essential. PET (Polyethylene Terephthalate) offers excellent thermal, mechanical, and barrier properties, but its natural flammability limits its use in fire-critical applications. This article outlines the decision-making process involved in selecting effective flame retardants tailored for PET applications.

1. Understanding PET's Chemical Nature

Before selecting additives, it's crucial to understand how PET behaves under heat:

- Thermal processing range: 250–280°C

- Crystalline polymer: Requires specific additive compatibility

- Prone to dripping when burned, potentially spreading fire

A successful flame retardant PET film application must prevent ignition, reduce smoke, and minimize melt dripping.

2. Criteria for Selecting Flame Retardants

When choosing flame retardants for PET, consider the following:

a. Thermal Stability

The flame retardant must withstand PET's high processing temperature without degrading.

b. Compatibility

It should not disrupt PET’s crystallinity, transparency, or mechanical properties—especially in custom flame retardant PET film applications.

c. Environmental Compliance

Must be RoHS, REACH, and often halogen-free. The best flame retardant for electronics is typically one that meets both fire and eco-regulatory standards.

3. Flame Retardant Classes for PET

Here are the most common flame retardant types used in PET systems:

- Phosphorus-based systems: Offer condensed-phase char formation and minimal smoke

- Nitrogen-phosphorus synergists: Popular in electronics and packaging

- Inorganic fillers (e.g., ATH, MDH): Lower flammability but may impact optical clarity

- Reactive flame retardants: Integrated into PET backbone, perfect for durable, non-migrating performance

When developing a custom flame retardant PET film, a blend of reactive and additive types is sometimes used to meet unique end-use requirements.

4. Application-Specific Selection Guide

| Application | Recommended Flame Retardant | Notes |

|---|---|---|

| Electronics | Halogen-free phosphorus-nitrogen | High thermal stability and UL compliance |

| Packaging | Additive phosphorus esters | Maintain clarity and processability |

| Construction | Inorganic fillers + synergists | Improve char, reduce smoke |

| Automotive | Reactive phosphorus systems | Enhanced durability and low toxicity |

Selecting the best flame retardant for electronics or other PET uses depends not only on safety performance but also regulatory and material compatibility.

5. Testing and Certification

No matter how well a system is designed, it must be validated:

- UL94 vertical and horizontal burn tests

- LOI (Limiting Oxygen Index)

- Glow wire tests (for electronics)

- Cone calorimetry (for smoke and heat release)

This is a standard part of the process when choosing flame retardants for PET to ensure compliance and performance.

Conclusion

Choosing the right flame retardant for PET is a balance of science, compliance, and application-specific requirements. Whether you're designing for electronics, packaging, or industrial systems, aligning chemical functionality with PET’s properties is crucial. From thermal stability to non-toxicity and regulatory approval, every factor plays a role in building the next generation of flame retardant PET film applications.

SEO Keywords:

choosing flame retardants for PET, flame retardant PET film applications, best flame retardant for electronics, custom flame retardant PET film, PET flame retardant selection, non-toxic flame retardant PET

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.